In less than three weeks of work, several innovations are already emerging from the mobilization activities of the TransMedTech Institute. Among them are two procedures for rehabilitating N95 masks, initiatives to which professors from Polytechnique Montréal, among others, are contributing.

On March 19, the TransMedTech Institute launched a call for needs, technological innovations and expertise, in the form of a competition called “Collaborative Initiatives to Address COVID-19 Challenges.” The goal was to identify and resolve urgent issues related to the infamous pandemic.

Of the 60 or so proposals submitted, about a dozen were designated “ultra-fast-track procedure.” Within a few days, teams of 15 to 20 engineers and healthcare professionals mobilized around the first projects.

By bringing interdisciplinary teams together to work agilely on issues being mentioned by the healthcare community, and in keeping with its living lab approach, the TransMedTech Institute is successfully accelerating the development and deployment of tools and protocols during the pandemic that normally take several months to see the light of day. And the Institute is well on its way to achieving its goals.

“We're moving forward at record speed,” says Carl-Éric Aubin, Chief Executive and Scientific Officer of the TransMedTech Institute, professor in the Department of Mechanical Engineering at Polytechnique Montréal, member of the Institut de génie biomédical, and researcher at Centre hospitalier universitaire (CHU) Sainte-Justine.

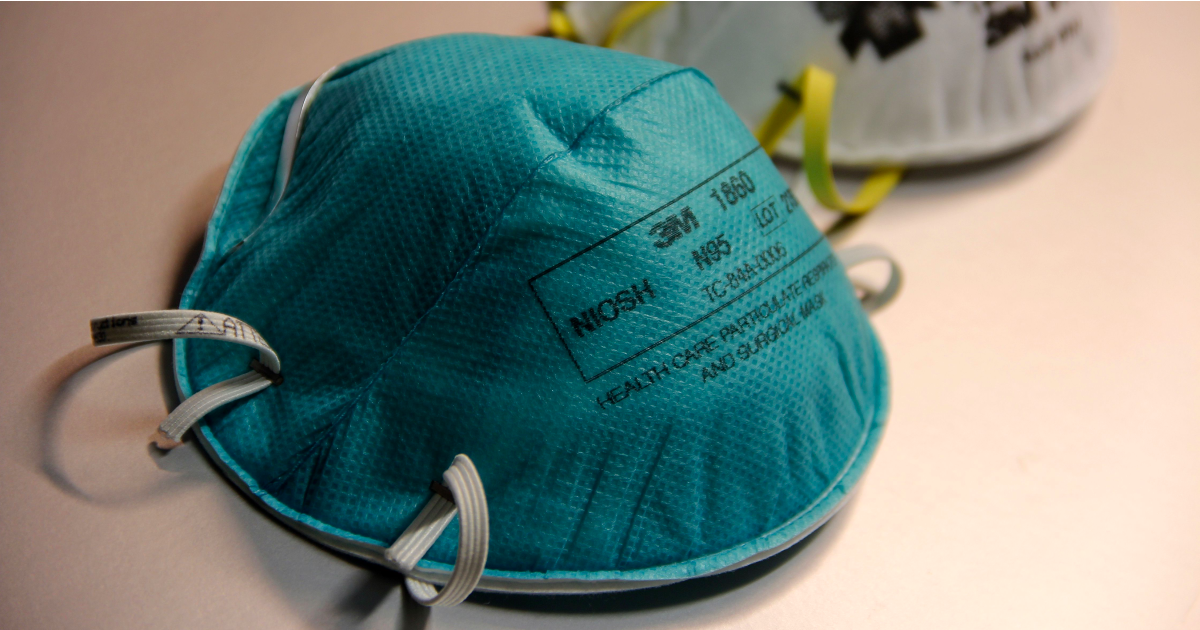

Reusing N95 masks

The engineer points out in passing that the teams that have been created are not skimping on the safety of the equipment or protocols they are developing. An example is the N95 respirator mask rehabilitation projects on which two teams are working.

One team, comprising among others Professor Michèle Prévost, Assistant Professor Étienne Robert and Professor Benoit Barbeau, from the Department of Civil, Geological and Mining Engineering at Polytechnique, is working to establish a protocol based on the vaporization of oxygen peroxide, a recently approved solution. Dr. Caroline Quach-Thanh, the physician in charge of infection prevention and control at CHU Saint-Justine, and her team are making certain of the feasibility of integrating this new protocol into the workflows of healthcare professionals. The interdisciplinarity of the researchers involved is essential to the implementation of these innovative solutions.

“The problem is that not all clinics and CHSLDs (long-term residential and care centres for seniors) have the capacity to disinfect in this way,” Professor Aubin explains. “So we're trying to adapt existing systems, such as nebulizers (mist sprayers), to enable them to do so.”

Another team, whose members include Caroline Boudoux, professor in the Department of Engineering Physics at Polytechnique, is looking at how ultraviolet disinfection of masks could be used on a large scale.

“Anyway, the problem is that it's not enough to disinfect the mask,” says Professor Aubin. "You also have to make sure its filtration properties are maintained.”

The researcher explains that the adjustable metal strips that shape the respirator closely around the nose are difficult to readjust to another person’s face. Guy Charron, Senior Advisor, Innovation, at the TransMedTech Institute, looked into this problem and designed a tool to reshape the adjustable strips.

According to Professor Aubin, validated and functional protocols for the rehabilitation of N95 respirators should be announced soon.

“Thanks to the incredible mobilization of many players, we hope to have completed the tests necessary to deploy a system within two or three weeks,” he says.

The TransMedTech Institute brings together the talents of its five founding institutions: Polytechnique Montréal, Université de Montréal, CHU Sainte-Justine, Centre hospitalier de l'Université de Montréal (CHUM) and the Jewish General Hospital of Montréal, in addition to some 50 partner institutions.

Find out more

Website https://www.polymtl.ca/transmedtech/en of the TransMedTech Institute

Expertise https://www.polymtl.ca/expertises/en/aubin-carl-eric of Professor Carl-Éric Aubin

Expertise https://www.polymtl.ca/expertises/en/prevost-michele of Professor Michèle Prévost

Expertise https://www.polymtl.ca/expertises/en/robert-etienne of Assistant Professor Étienne Robert

Expertise https://www.polymtl.ca/expertises/en/barbeau-benoit of Professor Benoit Barbeau

Expertise https://www.polymtl.ca/expertises/en/boudoux-caroline of Professor Caroline Boudoux

Website https://www.polymtl.ca/meca/en of the Department of Mechanical Engineering

Website https://www.polymtl.ca/biomed/ of the Biomedical Engineering program (In French)

Website https://www.polymtl.ca/cgm of the Department of Civil, Geological and Mining Engineering (In French)

Website https://www.polymtl.ca/phys/en of the Department of Engineering Physics

Website http://www.igb.umontreal.ca/ of the Institut de génie biomedical (In French)

Website https://www.chusj.org/en/Home of CHU Sainte-Justine

This article was first published on 8 April by Polytechnique Montréal.

A unique international forum for public research organisations and companies to connect their external engagement with strategic interests around their R&D system.

A unique international forum for public research organisations and companies to connect their external engagement with strategic interests around their R&D system.