Politecnico di Milano students Matteo Almondo, Davide Arnaboldi, Dario Corti e Simone Iovenitti designed a component that, after final qualification, will be mounted on the new D-Orbit’s ION MK2 spacecraft that will launch to space in August 2020.

The space component has been designed for the course “Additive Manufacturing for Space and Aerospace Applications”.

Students were asked to get their hands on the redesign of a real space component for Additive Manufacturing.

THE COMPETITION

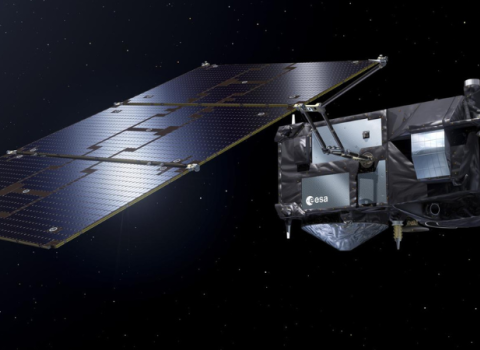

The students were asked to redesign for additive manufacturing a real space component, the support that connects the reaction wheels for attitude control of the ION Cubesat Carrier, a new version of a small spacecraft originally designed by D-Orbit for last mile delivery and positioning of CubeSat satellites. For this version of the spacecraft, D-Orbit is directly working with ESA, and their technology will also be employed for ESA’s Clean Space initiative on in-orbit servicing and active debris removal.

All teams were asked to minimize the weight of their redesigned support, comply with the mechanical requirements of the structure (static assessment and modal analysis) and optimize the manufacturability. Almondo, Arnaboldi, Corti and Iovenitti won the competition by presenting the best work among all the others: they were able to achieve the highest weight reduction (-65% with respect to the original weight of the component) observing all the mechanical and “printability” requirements.

The winning team was enthusiastic about the experience: “Designing a component that will go in space is something that few years ago would have been just a dream. Thanks to the collaboration between Politecnico of Milan, ESA and D-Orbit this has become reality! The best experience in the project was to learn how to work in a team. Each one of us has a different background and skills, to put them together was the key to success".

At the end of the project, the participants were engaged in a final presentation day that was held at the Department of Mechanical Engineering in front of a panel composed by prof. Tommaso Ghidini , prof. Bianca Colosimo, dr. Federico Ballo, and Italian start-up D-Orbit CTO Lorenzo Ferrario and Luca Bonino.

“The part selected for challenging the students’ engineering creativity was particularly relevant this year. First, the element has the crucial function of holding the reaction wheels, allowing every spacecraft to manoeuver in space. Moreover, this particular component will fly on a mission cleaning the orbits close to Earth from the un-operational satellites and debris in the frame of a very noble program of the European Space Agency, called Clean Space” said Tommaso Ghidini, Head of the Structures, Mechanisms and Materials Division at ESA – European Space Agency and professor of Additive Manufacturing for Space and Aerospace Applications.

“All seven groups of students and PhD Candidates” commented prof. Colosimo “were engaged in a real case-study that allowed them to measure-up with the complete process of Additive Manufacturing technologies. We have now successfully concluded the second edition of the course, which will be among our educational offer also for A.Y 2019-20, with Tommaso Ghidini as Visiting Professor”.

Lorenzo Ferrario and Luca Bonino of D-Orbit joined the panel during the day and in the selection of the winning team. "We have been extremely happy to take part in the project as test-case. We were really impressed by the quality of the results of the various project groups and were honored to take part in the judging committee. We at D-Orbit are strong supporters of the transition of the industry into Additive Manufacturing, as we enjoy the freedom this novel technology gives us during our design process. We look forward to continuing the collaboration with Politecnico di Milano and ESA on the topic" said Ferrario.

This communication first published 19 July 2019 by Politecnico di Milano.

A unique international forum for public research organisations and companies to connect their external engagement with strategic interests around their R&D system.

A unique international forum for public research organisations and companies to connect their external engagement with strategic interests around their R&D system.