An Imperial College London team designed a new, improved ventilator in one week, and gave away the technology to the whole world

Project manager of Jamvent, James Moore.

A shortage of ventilators emerged early on in the COVID-19 crisis as a critical problem around the world – so several groups of researchers got to work on solving it. One was at Imperial College London, where a team at the Department of Bioengineering quickly designed a low-cost ventilator that could be assembled from readily available parts anywhere in the world.

In an edited email exchange with Diane M. Fresquez of Science|Business, James Moore, the project manager, and his colleagues tell how it came together, despite lockdown.

Team: Project leader Joseph Sherwood, clinical leader Jakob Mathiszig-Lee, project manager James Moore, co-technical lead Michael Madekurozwa Institution: Imperial College London Research area: Ventilator designed for COVID-19 patients based on commonly available pneumatic parts Key funder: Imperial College London. Seeking manufacturers and links to health care providers on UK research-partnership platform Crowdhelix. Links: jamvent.com @ConsultImperial @MDDE_Imperial |

Q. Tell us about your Covid-19 project.

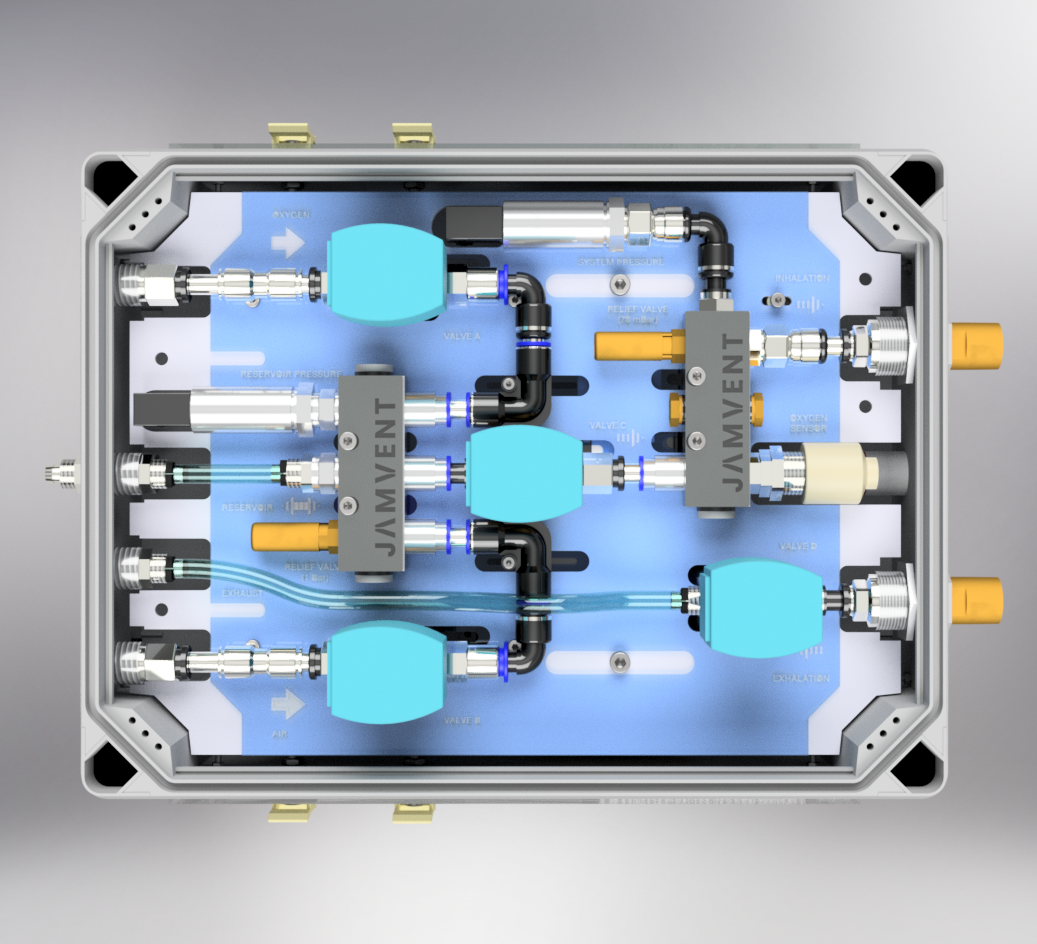

James Moore: JAMVENT is a low-cost emergency ventilator, developed in response to the COVID-19 outbreak. The design is an improvement on standard ventilators. It’s open access, meaning free to use, anywhere during the COVID-19 crisis. It’s easy to manufacture and supply; and it can perform all the tasks required of an intensive care unit ventilator for COVID-19 patients.

Q. What were some of the challenges you faced during the development phase?

Jakob Mathiszig-Lee: The start was incredibly intense. I was and am still working full-time managing COVID patients in a very busy ICU (at Royal Brompton Hospital). When not at the hospital, I was in the lab (I have an amazingly understanding wife) and would occasionally finish a nightshift and go straight to the college. Being on a deserted campus was sometimes like being in the post-apocalyptic virus-themed film, I Am Legend.

James Moore: The first challenge back in mid-March, when we began, was that only one of our teammates, Jakob Mathiszig-Lee, had any prior experience with ventilators. Fortunately, his experience treating COVID patients was crucial in establishing design criteria. It also helped that he has excellent engineering skills. The rest of us learned quickly and we had a basic design for JAMVENT done within one week.

Jakob Mathiszig-Lee

We purposefully avoided the “bag-squeezing” approach that you see in most emergency-use ventilators because Jakob knew it wouldn’t perform all of the functions required for COVID patients; our design, for instance, can precisely control the air pressure in the lungs after exhalation. Also, basing a design on specialised hospital items like bag valve masks would have made our design susceptible to supply shortages. COVID-19 has placed the medical supply chain under strain due to unprecedented demand for equipment – but our design uses relatively inexpensive and readily available parts. I’ve been involved in other medical device development projects, but never one that moved a swiftly as this.

Joseph Sherwood: The first six weeks were day and night, every day, but the rate of progress was a strong motivator. I have been inspired by the number of people who have freely offered their time or resources to the project. The pace of this project has not left us much time for our families, so we sometimes have to decide as a group to take a particular day off to save our sanity -- three times so far!

Michael Madekurozwa: The biggest challenge has been not burning out (too much). I have also used my journey in and out of work to reflect and unwind.

|

The importance of ventilators during the COVID-19 pandemic · 30 per cent of all hospitalised patients with the coronavirus develop severe pneumonia and require mechanical ventilation. · 800,000 ventilators are needed worldwide to deal with the Covid-19 outbreak. · Without sufficient equipment, 30 per cent of those hospitalised will die from complications due to pneumonia. www.jamvent.com |

Q. How is JAMVENT different from other ventilators?

James Moore: JAMVENT provides a simple, low-cost solution to current ventilator shortages worldwide, particularly for health services in developing countries. Ten weeks after beginning this project, we submitted testing data from a fully functional prototype to the Food and Drug Administration in the US to apply for Emergency Use Authorization. Until COVID-19 came along, there wasn’t much motivation to improve or simplify ventilator design, and there is definitely a market for JAMVENT even after this pandemic subsides.

The design can be used by anybody, but for those who want to buy it ready-made we have partnerships with three medical device manufacturers: Pathfinder Medical, RPD International and TestWorks. We have made the details of the design freely available so that other manufacturers globally can produce the ventilator and take advantage of the low supply chain requirements that are at the centre of the JAMVENT design. We encourage people to register for design downloads via our website so they can be notified of updates.

Madekurozwa

Q. Where does the name JAMVENT come from?

James Moore: Like everything on this project, coming up with a name was a fast-paced activity. We tried using the initials of our names, but quickly realised that we didn’t have much “alphabetical diversity” and no vowels. The letters J and M obviously stood out, and some of us are musicians, so we named it JAMVENT. I play bass and ukulele, and I sing. Joseph plays guitar, bass and also sings. We have a departmental band, called the Gastric Band, that plays at graduation and the Christmas party.

Joseph Sherwood

Q. What is your advice to policy makers, based on your experience?

We hope the lesson has been learned that preparation for such future emergencies is crucial. We have to expect this will happen again. We need to establish plans for minimising the damage to humanity and the economy with early, well-targeted action, including communication, testing capabilities and taking equipment availability into consideration.

A unique international forum for public research organisations and companies to connect their external engagement with strategic interests around their R&D system.

A unique international forum for public research organisations and companies to connect their external engagement with strategic interests around their R&D system.