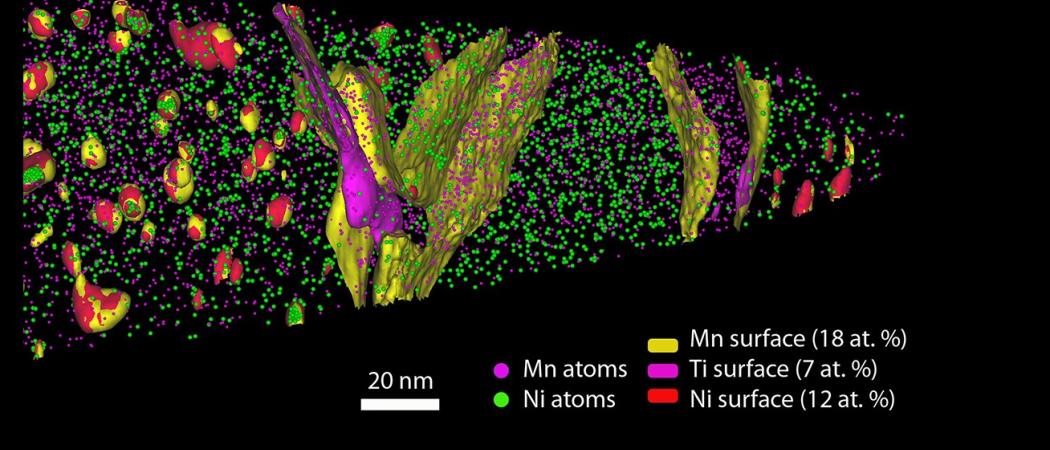

An atom probe is coming to Trondheim that will enable researchers to see which atoms a mineral or material consists of. This research is vital to developing the kinds of building blocks needed for green technologies, such as batteries, solar cells, and wind turbines. Illustration photo from the Max-Planck-Institut für Eisenforschung GmbH

NTNU, the Geological Survey of Norway and SINTEF have joined forces to establish a national research laboratory on minerals and materials to help society make the transition to a greener economy.

Green technologies need new and customized minerals and materials. Solar panels, super magnets, batteries and new building materials are being developed from raw and other materials with very special properties and qualities.

To this end, researchers need to be able to investigate materials and minerals, often down to the atomic level, to better understand the kinds of qualities and properties a substance has. This is what researchers call material characterization.

A national laboratory for characterizing minerals and advanced materials is currently being established in Trondheim. It is called the Norwegian Laboratory for Mineral and Materials Characterisation (MiMaC), with NTNU, NGU and SINTEF at the helm of its creation.

From mineral to material

“With MiMaC we can research the entire value chain, from mineral to finished materials,” says Jostein Mårdalen, who heads NTNU’s Department of Materials Technology.

The results from the laboratory will contribute to developing even better methods to create materials from minerals.

“We can also help manufacture products and raw materials with tailor-made properties for specific applications.

Mårdalen explains why it’s useful for researchers to look at the entire value chain.

“There’s a reciprocal relationship between minerals and materials: The mineral industry has to deliver new minerals and mineral products with new qualities when the need for them arises in the materials industry. At the same time, the materials industry has to exploit the resources and opportunities found in the mineral industry. With MiMaC we can develop and improve that collaboration.”

“This type of equipment makes the laboratory a world leader. Being able to see every single atom in a sample is actually extremely powerful, “says Mårdalen.

“In addition, we can help ensure that extraction and production happens in an environmentally friendly and efficient way,” says Mårdalen.

Through the eye of the needle

MiMaC was one of nineteen projects that made it through the eye of the needle and received funding from the Research Council of Norway’s national financing initiative for research infrastructure in 2017. A total of 92 projects applied for funds.

Mårdalen believes two factors led to their research project receiving NOK 71 million from the Research Council.

- One factor is that the approach of researching the entire value chain, from mineral to material, is innovative in the field. This will have a major ripple effect when students take that perspective into industry.

- The second factor is that MiMaC will act as a national laboratory, accessible to both researchers and the mineral and materials industry, with new and advanced equipment that has not been available until now.

The photo shows a 0.03 millimetre thick cross-section of gneiss from Rogaland county. Researchers are able to view images like this under a microscope.

A large portion of the budget will pay for the purchase of expensive laboratory equipment. The most expensive instrument is an atom probe, which costs around NOK 40 million.

“The atom probe allows us to pick out a sample and see exactly what atoms make up the sample. We can create a 3D model where we locate every single atom in the sample. This type of equipment makes the laboratory a world leader in the field and is well worth the investment. Being able to see every single atom in a sample is actually extremely powerful,” says Mårdalen.

Valuable collaboration

Henrik Schiellerup from the Geological Survey of Norway (NGU) says that MiMaC will also be of major importance for NGU mineral scientists.

“The MiMaC instruments will play an important role as a common platform for mineral and materials research,” he says.

“With MiMaC, we’ll be able to bring together the best expertise from two fields that have a lot in common. We hope that establishing MiMaC will lead to more collaboration between institutions and related disciplines,” says Schiellerup.

Important in the shift to a greener world

“We need ever more specialized and tailor-made materials. Today, we could build the Eiffel Tower more than twice as high with the same amount of steel – which shows how far we’ve come. And development won’t stop here,” says Schiellerup.

The transition to greener technologies is high on the agenda for both mineral and material researchers.

“We’re completely dependent on new minerals and materials to help us transition to greener technologies, such as to develop better solar panels, and build wind turbines and smart buildings. These are challenges that the new laboratory technology will help solve,” he says.

This release was first published 29 August 2018 by Gemini Research News.

A unique international forum for public research organisations and companies to connect their external engagement with strategic interests around their R&D system.

A unique international forum for public research organisations and companies to connect their external engagement with strategic interests around their R&D system.